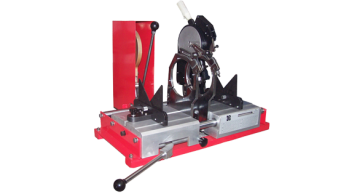

WORKSHOP WELDING MACHINE SHT 160, 315

Suitable for Lengthning short injection molded fitting in a workshop or produce an integrated fittings

SHT

160/63

Workshop Fitting Machine SHT 160/63

Application

and features:

- Suitable for

butt welding of plastic pipes and / or fittings made of PE, PP, and PVDF in a

ditch in worksite or workshop.

- Also used to

install drainage system in building.Specially designed clamps according to

features in structure and dimension of fitting indrainage system.

- Removable

PTFE coated heating plate with high accurate temperature control system.

- Electrical

planing tool with safety limit switch enables it to be started only when it is

locked in operation position .

- Mechanical

lock to maintain welding pressure.

- Spring

manometer provides correct welding pressure.

- Pivoting

planing tool an heating plate bring convenience to placing and removing.

Optional parts:

- Various

special clamps for installtion of drainage system in building.

Technical parameters:

|

Model |

SHT 160/63 |

|

Pipe size(mm) |

50,63,75,90,110,125,140,160 |

|

Application |

Pipe with

pipe of fittings; fitting with fittings |

|

Heating

Plate Max. Temp. |

260℃ |

|

Temp.

deviation in surface(170~250℃) |

≤±7℃ |

|

Working

Voltage |

220V、50Hz |

|

Planing

tool power |

0.8 KW |

|

Hydraulic

unit power |

0.6 KW |

|

Total

power |

1.4 KW |

|

Weight |

40Kg

(Don`t include optional parts) |

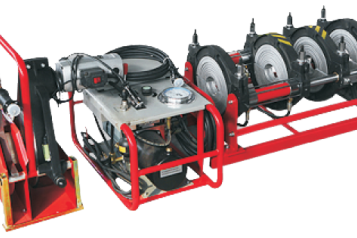

SHT

315/90

Workshop Fitting Machine SHT 315/90

Application

and features:

- Suitable for

butt welding of plastic pipes and / or fittings made of PE, PP, and PVDF in a

ditch in worksite or workshop.

- Also used to

install drainage system in building.Specially designed clamps according to

features in structure and dimension of fitting indrainage system.

- Removable

PTFE coated heating plate with high accurate temperature control system.

- Electrical

planing tool with safety limit switch enables it to be started only when it is

locked in operation position .

- Mechanical

lock to maintain welding pressure.

- Spring

manometer provides correct welding pressure.

- Pivoting

planing tool an heating plate bring convenience to placing and removing.

Optional parts:

- Various

special clamps for installtion of drainage system in building.

Technical parameters:

|

Model |

SHT 315/90 |

|

Pipe

size(mm) |

110,160,180,200,225,250,280,315 |

|

Application |

Pipe with

pipe of fittings; fitting with fittings |

|

Heating

Plate Max. Temp. |

260℃ |

|

Temp.

deviation in surface(170~250℃) |

≤±7℃ |

|

Working

Voltage |

220V、50Hz |

|

Planing

tool power |

3.5KW |

|

Hydraulic

unit power |

1.1KW |

|

Total

power |

4.6KW |

|

Weight |

250Kg

(Don`t include optional parts) |