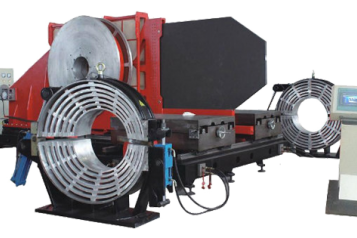

HYDRAULIC BUTT FUSION WELDING MACHINE SHD 800, 1200

Suitable for PE, PP, PVDF it is convenient to butt welding plastic pipe or fittings suitable for field or workshop

SHD 800/450

Hidraulic Butt Fusion Welding

Machine SHD 800/450

Application

and Features:

- Suitable

for butt welding of plastic pipes and fittings made of PE, PP and PVDF in a

ditch in worksite or workshop.

- Consists

of basic frame, hydraulic unit, planing tool, separate heating plate, support

for planing tool & heating plate, and optional parts.

- Removable

PTFE coated heating plate with high accurate temperature control system.

- Electric

planning tool with safety limit switch enables to start it only when it is

locked in operation position.

- Made

of lightweight and high strength material.

- Low

starting pressure and high reliable seal structure.

- Changeable

welding position brings more convenience while welding various fittings.

- Separate

two-channel timer records times in soaking and cooling phases.

- High-accurate

and shockproof pressure meter indicates clearer readings.

- Labor

saving and high efficient crane is available to lift planing tool and heating

plate.

Optional parts:

- Stub

end device for short flange stub

- Data

logger.

- Trolley

Technical Parameters:

|

Model |

SHD 800/450 |

|

Pipe size(mm) |

450,500,560,630,710,800 |

|

Heating plate max. temp. |

270℃ |

|

Temp. deviation in surface(170~250℃) |

≤±7℃ |

|

Pressure adjustable Ranges |

0-16Mpa |

|

Working voltage |

220V、50Hz |

|

Heating plate power |

12.5KW |

|

Planing tool power |

2.2KW |

|

Hydraulic unit power |

3KW |

|

Crane power |

0.5KW |

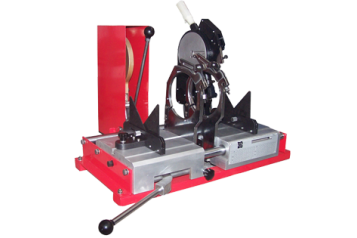

SHD 1200/800

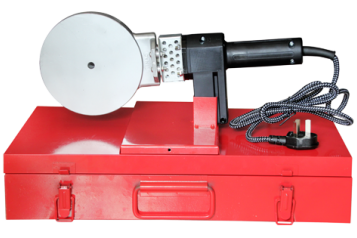

Hidraulic Butt Fusion

Welding Machine SHD 250/90

Application and Features:

- Suitable

for butt welding of plastic pipes and fittings made of PE, PP and PVDF in a

ditch in worksite or workshop.

- Consists

of basic frame, hydraulic unit, planing tool, heating plate, support for

planing tool & heating plate, and optional parts.

- Removable

PTFE coated heating plate with high accurate temperature control system;

- Electrical

planing tool.

- Be

made of lightweight and high strength material; simple structure, small and

delicate, user friendly.

- Low

starting pressure ensures reliable welding quality of small pipes.

- Changeable

welding position enables to weld various fittings more easily.

- High

accurate and shockproof pressure meter indicates clearer readings.

- Separate

two-channel timer records time in soaking and cooling phases.

Optional parts:

- Stub

end device for short flange.

- Data

logger.

Technical Parameters:

|

Model |

SHD 250/90 |

|

|

Pipe size (mm) |

90,110,125,140,160,180,200,225,250 |

|

|

Heating plate max. temp. |

270℃ |

|

|

Temp. deviation in surface (170~250℃) |

≤±7℃ |

|

|

Pressure adjustable Ranges |

0-6.3Mpa |

|

|

Working voltage |

220V、50Hz |

|

|

Heating plate power |

3KW |

|

|

Planing tool power |

1.1KW |

|

|

Hydraulic unit power |

0.75KW |

|

|

Total power |

4.85KW |

|

|

Weight |

143Kg |

|

|

Packing |

Cases |

3PlywoodCases |

|

Volume |

0.70CBM |

|